White Metal Bearing Services

The repair of White Metal Bearings to customer’s instructions has been a big part of our business for over a hundred years.

Bearing Repair Services for Breakdowns and Routine Maintenance

We are approved repair and refurbishment contractors to end-users across the range of multi-nationals to development start-ups in the engineering, defence, maritime, oil & gas and electricity supply industries. We can repair almost every type of white metal bearing from large thrust and journal bearings for power generating equipment to small bushes for high-speed compressors.

Refurbishment & Repair

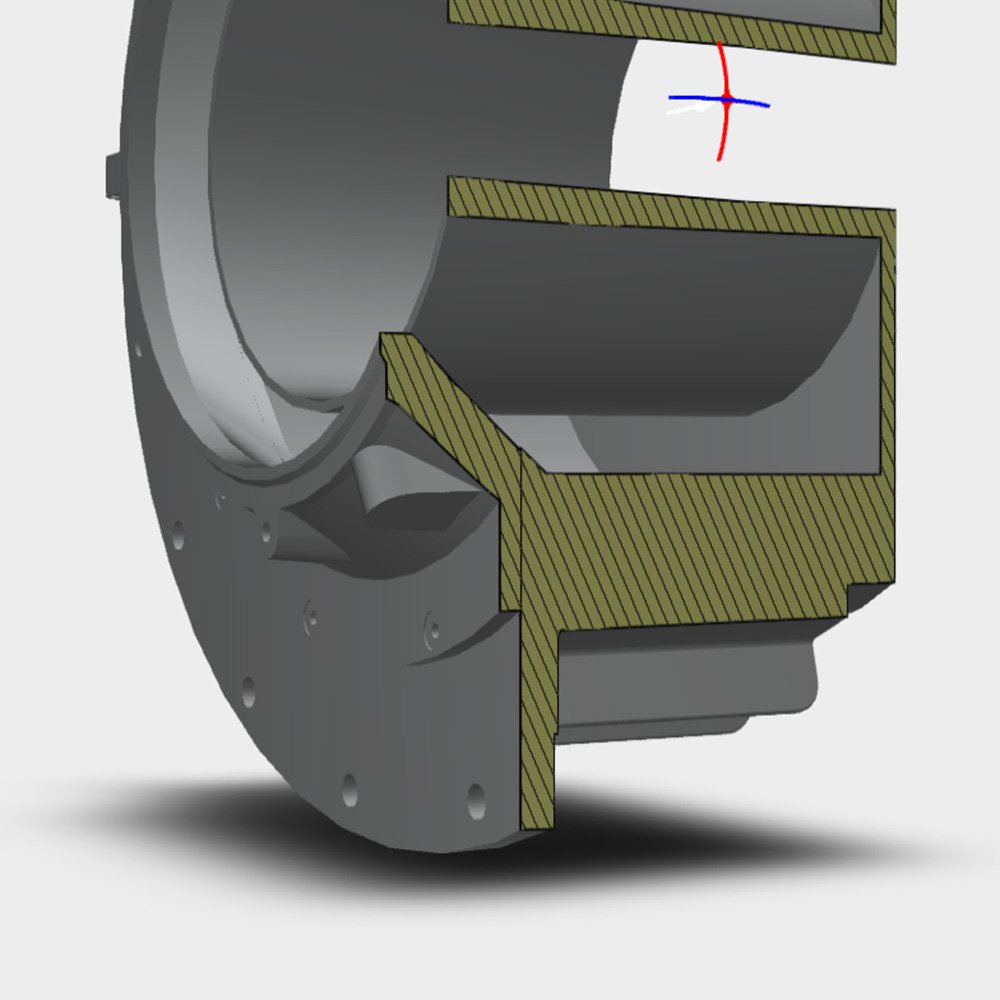

Coleherne’s bearing repair experience covers almost every type of journal or thrust bearing. Our designated team of bearing repairers work in their own specialist area alongside our bearing manufacturing workshop. Almost every type of white metal bearing, associated components and even whole bearing assemblies can be repaired.

Coleherne offers a full inspection on receipt procedure and bearing failure assessment.

On approval of our repair quotation, we will conduct a full bearing refurbishment, final inspection and NDT process within our white metal bearing repair facility.

We use the same metalling and machining processes, non-destructive testing and dimensional criteria are applied to repaired and new bearings:

Full inspection on receipt procedure

Bearing failure assessment

Repair and re-engineering options costed and agreed

Melt-off worn white metal lining

Grit blast and apply special coatings to the bearing backing

Immersion tinning to restore the bonding layer

Depending on the form of the backing, either centrifugal or static re-lining

Proof machining

Ultrasonic and dye penetrant to agreed standards

Removal of excess whitemetal from joint faces

Final machining of the whitemetal to standard or agreed dimensions

Ultrasonic and dye penetrant testing to agreed standards

Final dimensional inspection

Protection, packaging, certification and delivery.

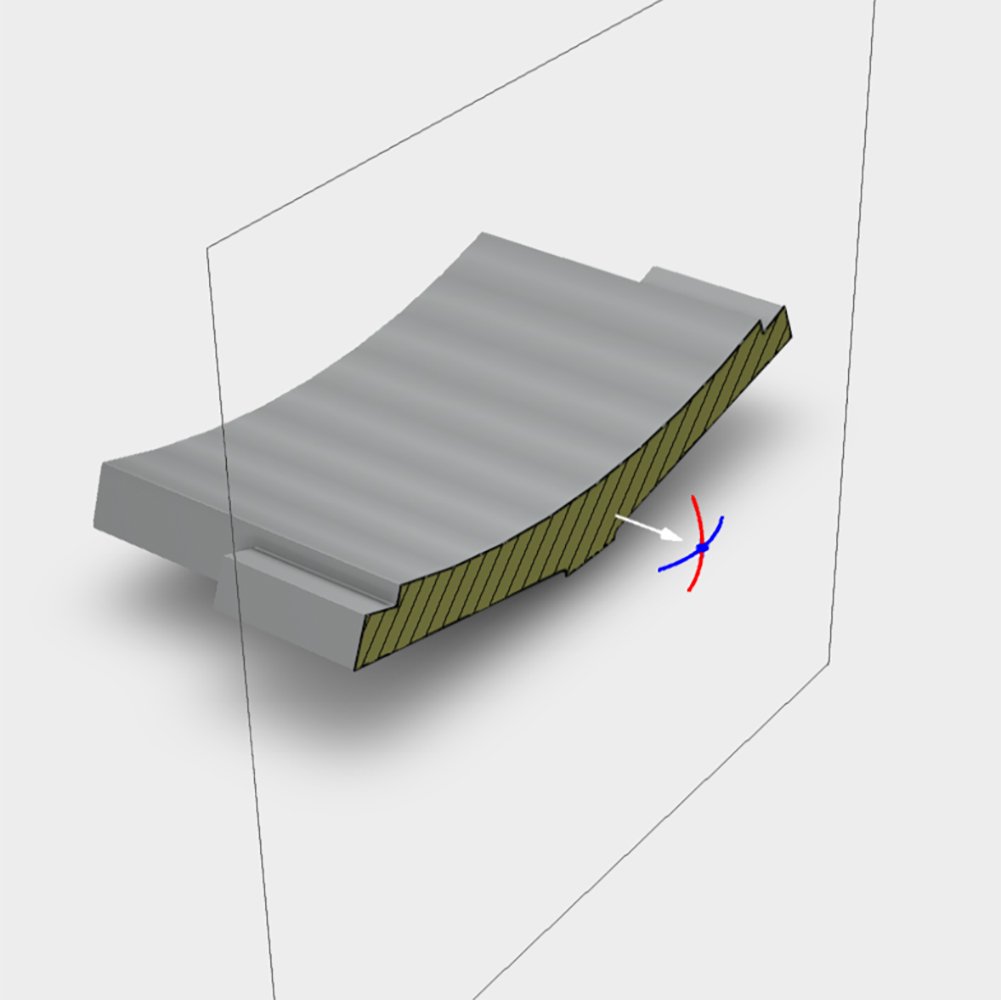

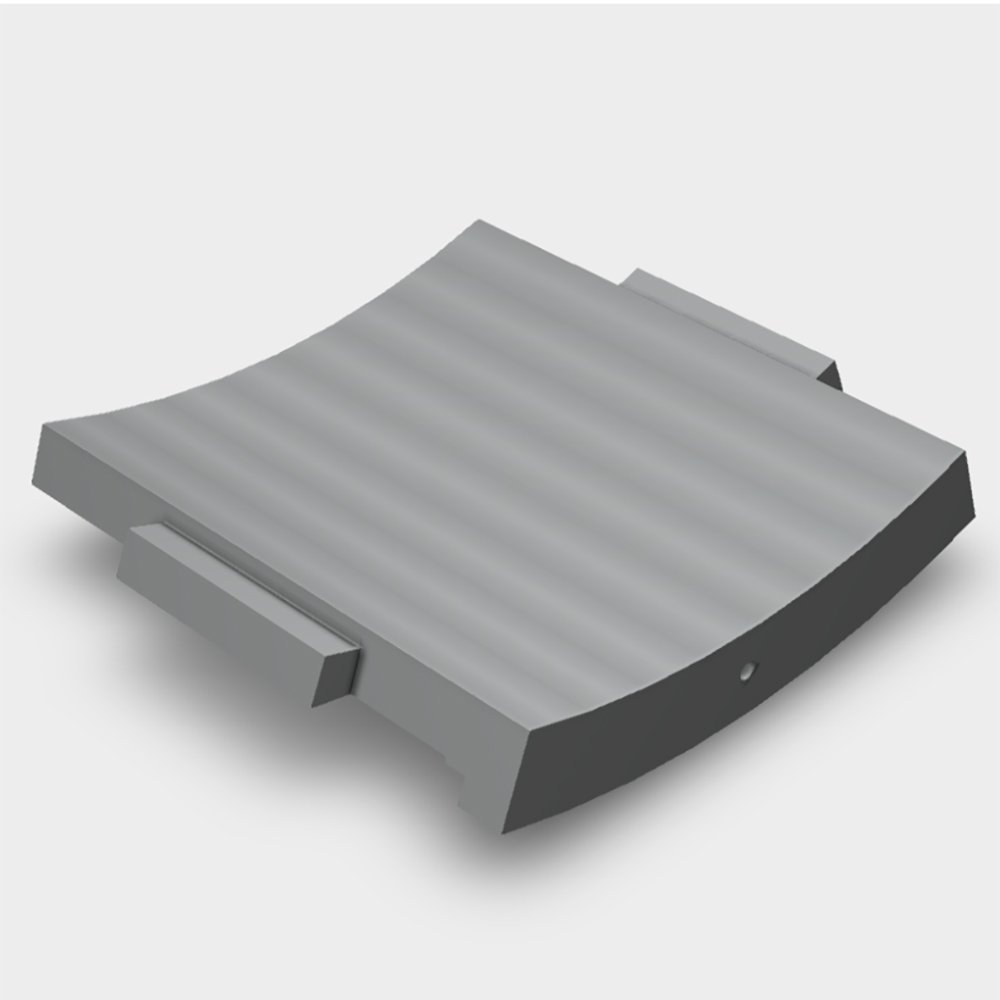

Repairing Thrust Pads For The UK’s Biggest Pump Storage Hydro Station

High Accuracy is assured through our use of our high end Zeiss Calypso co-ordinate measuring machine

Repairing Thrust Assemblies in a Japanese Compressor

Emergency Repairs And Outages

We recognise that turnaround can often be critical, and we will do whatever it takes to meet the agreed delivery schedule.

Before

After

Reverse Engineering and Re-Engineering

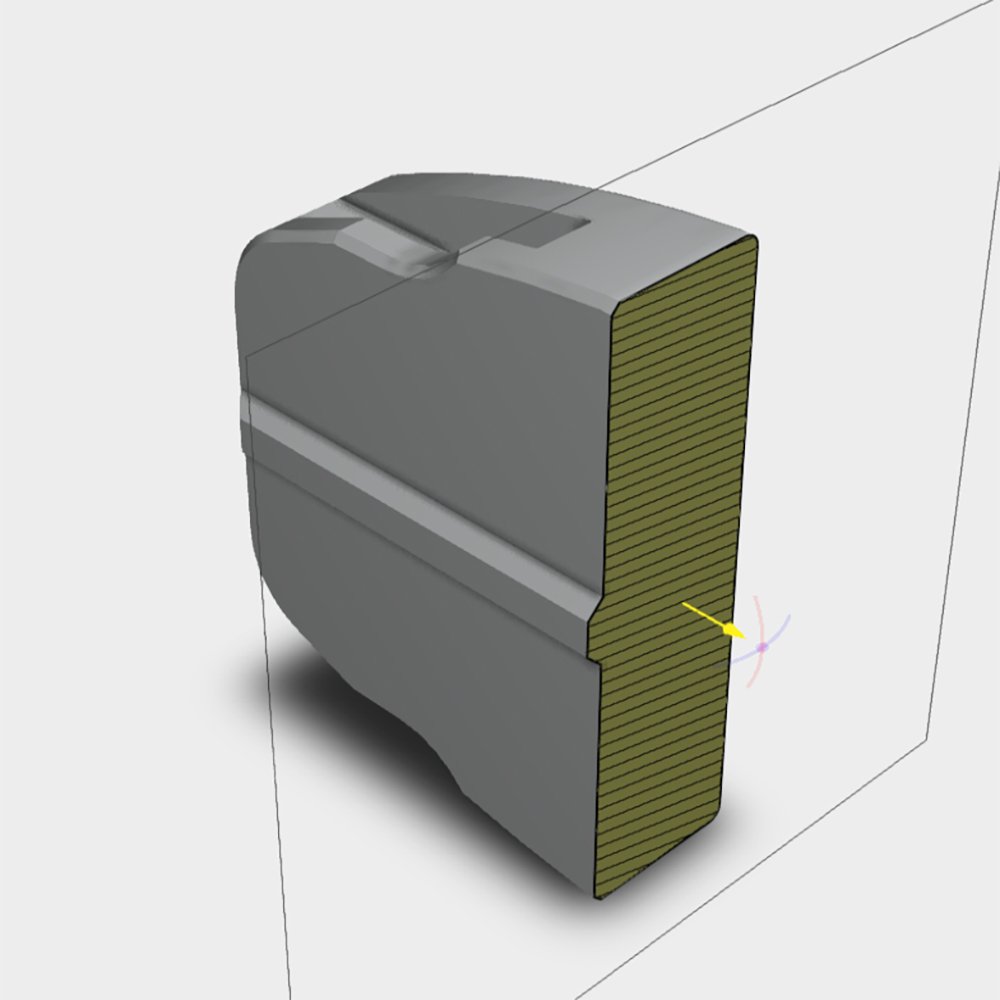

Coleherne use 3D laser scanning for reverse engineering of parts for which no drawing is available. Using the Creaform non-contact measuring system, our technical staff digitally scan and capture data to determine the exact shape of parts presented to us. Our engineers can then assess and confirm the critical bearing bores, fit diameters, fit lengths etc in order to produce a manufacturing drawing.

When bearing performance needs to be improved, our engineers can investigate the bearing system and using our bearing analysis software, propose new or improved bearing designs or clearances to end-users.

Creaform Non-Contact Measuring System

Reducing Power Losses In Gas Turbine Thrust Pads